Ever wonder why lactate sensors are such a big deal? Whether you’re an athlete keeping tabs on your performance, a healthcare pro diagnosing conditions, or just a tech enthusiast, these little gadgets play a vital role. But here’s the thing: keeping them stable and reliable isn’t always a walk in the park. One effective approach to enhancing sensor stability is the use of additive-free enzyme solutions. This method offers several advantages, which we explore in depth in our article The Benefits of Using Additive-Free Enzyme Solutions in Diagnostics.

In this article, we’re going to break down the five common challenges that can throw your lactate sensors off their game, and—more importantly—how to tackle them. By the end, you’ll be armed with the know-how to keep those readings sharp and trustworthy.

1. The Temperature Tango

Lactate sensors can be a bit like Goldilocks when it comes to temperature—everything needs to be just right. Too hot or too cold, and the sensor’s enzyme activity, which is the heart of the operation, can go haywire, leading to unreliable readings.

Solution: Dance with Temperature Compensation

To keep things on track, many modern lactate sensors come with built-in temperature compensation features. These handy mechanisms adjust the readings based on the surrounding temperature, so you get accurate results no matter the weather. Also, a little common sense goes a long way: store your sensors in a consistent, stable environment and use them within the recommended temperature range to avoid any unwelcome surprises.

2. Enzyme Wear & Tear

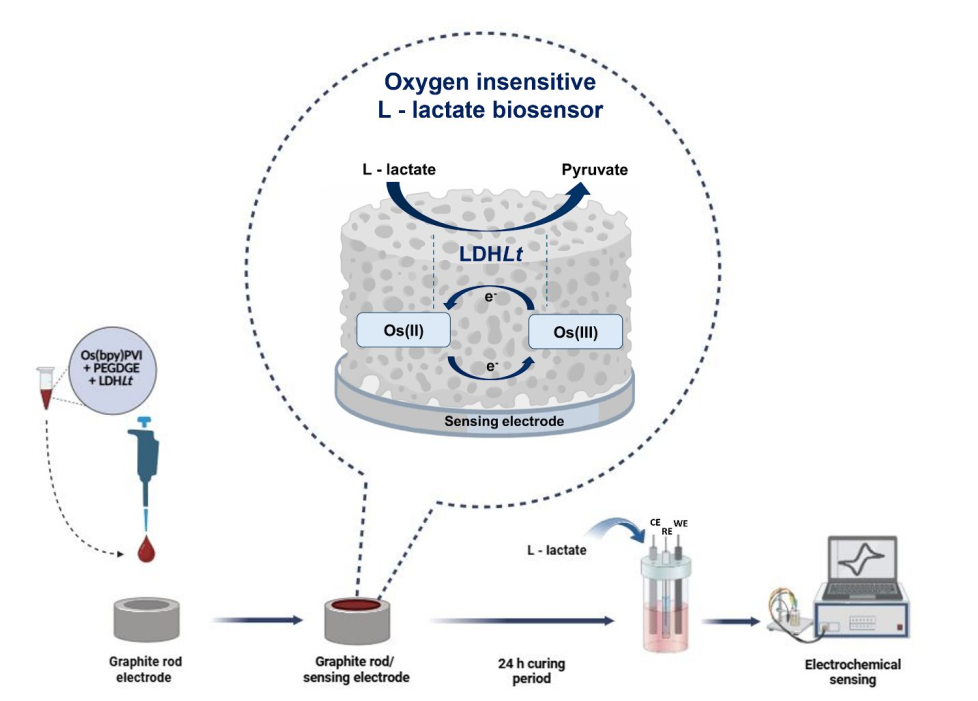

The workhorse inside your lactate sensor is typically an enzyme like lactate oxidase. But, like any hardworking component, it can degrade over time, especially when exposed to harsh environmental conditions. When this happens, the sensor’s accuracy can start to slip.

Solution: Armor Up with Protective Coatings and Smart Storage

To keep things on track, many modern lactate sensors come with built-in temperature compensation features. These handy mechanisms adjust the readings based on the surrounding temperature, so you get accurate results no matter the weather. Also, a little common sense goes a long way: store your sensors in a consistent, stable environment and use them within the recommended temperature range to avoid any unwelcome surprises.

3. Unwanted Interference

Sometimes, your lactate sensor has to deal with uninvited guests—substances like ascorbic acid (vitamin C), uric acid, or acetaminophen that can mess with the readings. It’s like trying to have a conversation at a loud party; too much background noise and things get confusing.

Solution: Armor Up with Protective Coatings and Smart Storage

To filter out these party crashers, many sensors use selective membranes designed to let the good stuff through while blocking out the riffraff. On top of that, regular calibration with known standards can help fine-tune your sensor, ensuring it’s focused on what really matters.

4. The Strain of the Game

Athletes, this one’s for you: when you’re pushing your body to the limit, your lactate sensor is along for the ride. Unfortunately, all that movement can subject the sensor to mechanical stress, potentially damaging its delicate components and leading to wonky readings.

Solution: Built Tough and Handled with Care

The good news is that manufacturers are continually improving the design of lactate sensors, making them more robust and able to withstand the rigors of intense physical activity. However, it’s still crucial to handle them with care—avoid unnecessary bending or pressure, and always follow the usage instructions to keep your sensor in fighting shape.

5. The Gunk Buildup

Over time, the electrodes in your lactate sensor can become fouled by proteins and other substances, like grime on a window. When that happens, the sensor’s ability to measure lactate levels accurately can take a hit.

Solution: Keep it Clean with Regular Maintenance

To keep those electrodes sparkling, regular cleaning as per the manufacturer’s guidelines is key. Some sensors even come with self-cleaning mechanisms or easily replaceable electrodes, making upkeep a breeze. And remember, careful sample handling can go a long way in preventing contamination in the first place.

Lactate sensors are incredible tools, but like anything worthwhile, they need a little TLC to perform their best. By staying on top of challenges like temperature fluctuations, enzyme degradation, interference, mechanical stress, and electrode fouling, you can ensure your sensor stays reliable and accurate. A bit of care and attention now means fewer headaches later—and more dependable readings when it really counts.